Specifications

NewBlot PVDF Stripping Buffer is supplied as 5X concentrated solutions. Each 100 mL bottle is sufficient for up to 3000 cm2 or approximately fifty 7 x 8.5 cm Millipore® Immobilon®-FL PVDF membranes.

NewBlot PVDF stripping buffer contains hazardous materials and additional shipping costs will be applied.

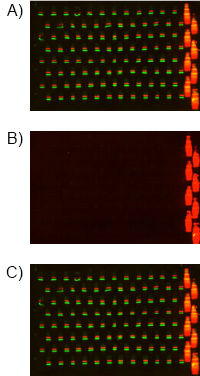

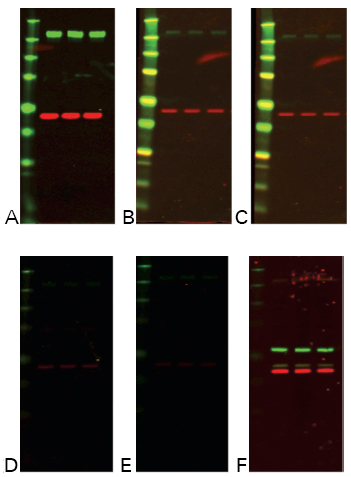

Example Data

Factors Affecting Efficiency when Using NewBlot PVDF Stripping Buffer

Recommended standard conditions: 1X NewBlot PVDF for 20 min at room temperature.

Below are factors that affect stripping efficiency with NewBlot PVDF on PVDF membranes. Figure 2 above shows the effects of incubation time and addition of SDS on stripping efficiency. These blots and protein targets were not sufficiently stripped using the standard Procedure, and optimization was performed.

For optimal stripping results, follow the optimization guidelines in NewBlot PVDF Stripping Buffer pack insert.

Amount of time blot is in stripping buffer

Stripping time has the greatest effect on efficiency.

Increasing the stripping time may lead to increased damage/loss of target antigens, and reduce the success of reprobing.

Sample type and preparation

Even under the most stringent stripping conditions, the fluorescent signal may not be removed completely due to sample load amount, antibody affinity/avidity, and target protein abundance.

Blot handling conditions

Washing, scanning, or stripping efficiency will be affected if the blot is allowed to dry at all during incubation. Keep the blot moist at all times.

Detergent may help remove fluorescent signal

If fluorescent signal remains, try longer incubation times first, followed by addition of SDS.

Temperature used for stripping

If fluorescent signal remains after the above steps, incubation in stripping buffer may be carried out at 37 °C using a water bath or incubator. This should only be attempted if the above optimization steps are unsuccessful.